Stainless Steel Cargo Net: Optimal Truck Cargo Covering Solution

Zoo Animal Enclosures Construction: Key Tips for Animal Safety

01/08/2026

Stainless Steel Outdoor Aviary Netting: Top Choice for Eco-Friendly Aviaries

01/22/2026In today’s rapidly evolving global logistics industry, the safety, compliance, and efficiency of cargo transportation have become integral components of a company’s core competitiveness. For Canada’s vast highway transportation network, trucks serve as the primary carriers for goods. Their cargo covering solutions directly impact transport safety, cargo integrity, and regulatory compliance. Stainless steel rope nets, with their exceptional performance advantages, are increasingly becoming the benchmark choice for truck cargo coverage. Recently, samples of our stainless steel cargo net, embodying our commitment to quality, departed our factory en route to our Canadian client. We look forward to our products delivering a new standard of safety, durability, and efficiency in cargo coverage for the local transportation industry.

Full Process for Sample Dispatch

Precision-matched Solutions, Customized Sample Preparation

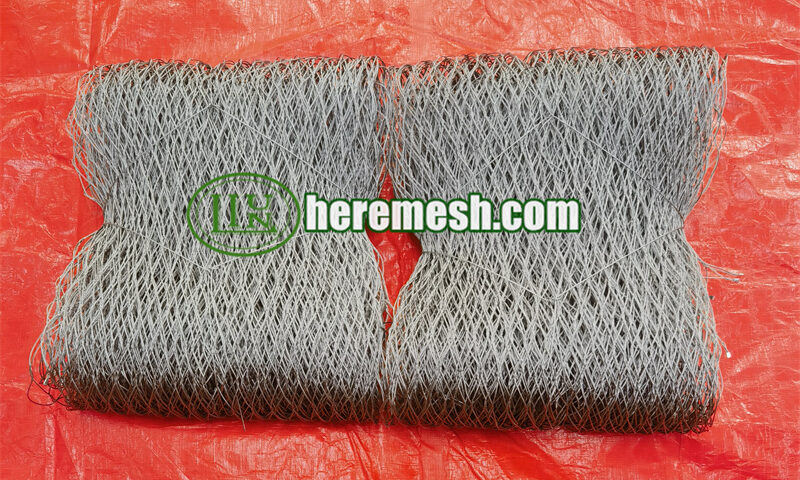

Upon receiving an inquiry from a Canadian user, our technical team promptly engaged in an in-depth discussion with them. We gathered details about the client’s intended application and the environmental conditions in their region. Based on these core requirements, we specifically recommended 304 stainless steel rope net products. This material perfectly matches Canada’s complex transportation environment in terms of corrosion resistance, tensile strength, and low-temperature stability. To enable the client to comprehensively evaluate product performance, we manufactured two samples for shipment. These samples facilitate tensile testing, abrasion resistance testing, and practical vehicle loading compatibility trials.

Rigorous Quality Control Testing Ensures Samples Meet Quality Standards

Before shipping samples, we conduct quality inspections on every stainless steel cargo net. First, we test the tensile strength of the nets using specialized equipment to ensure each stainless steel wire’s breaking strength can withstand the jolts, pulls, and wind impacts during truck transportation. Additionally, we inspect the weaving process to guarantee uniform mesh openings, secure knots, and the absence of quality issues like loose threads or skipped stitches.

After multiple layers of inspection, all samples meet industry premium standards and comply with Canadian transportation safety requirements for cargo covers (such as load-bearing capacity). Subsequently, we employ dual-layer packaging designed for moisture resistance and abrasion protection. The inner layer uses PE film wrapping to prevent moisture absorption during transit. The outer layer utilizes waterproof fabric sealing to avoid deformation or damage caused by impacts during international shipping.

Efficient Logistics Distribution, Precise Delivery

Considering the time-sensitive and security-critical nature of the samples, we selected the most efficient and convenient shipping solution. On the day of dispatch, we completed all customs documentation preparations to ensure swift clearance. Departing from our domestic factory, the samples arrived in Canada via international express delivery. They were delivered precisely to the customer’s designated address within the estimated timeframe. Throughout the entire shipment, we provided the customer with a tracking number, enabling real-time monitoring of the samples’ location for full transparency and control. The successful delivery of these samples not only demonstrates our efficient supply chain responsiveness but also underscores our solemn commitment to “quality delivery”.

Stainless Steel Cargo Net: Why It’s the Preferred Choice for Truck Cargo Coverage

In the field of truck cargo covering, traditional covering materials present numerous drawbacks. Canvas is heavy, poorly ventilated, and prone to mold growth and tearing with prolonged use. Standard plastic netting has low tensile strength and poor weather resistance, becoming brittle and prone to cracking in cold temperatures. While nylon netting is lightweight, it lacks sufficient abrasion and corrosion resistance, resulting in a short service life. The advent of stainless steel rope netting addresses these shortcomings. Leveraging dual advantages in material composition and structural design, it has emerged as the ideal solution for truck cargo coverage.

Superior Material, Excellent Weather & Durability Performance

Our stainless steel cargo net, primarily made from 304 or 316L stainless steel. 304 stainless steel offers excellent corrosion resistance, withstanding exposure to rainwater, snowmelt, and salt spray. It remains rust-free and non-brittle even in severe winter cold or coastal humid environments. This material boasts a service life exceeding 10 years, far surpassing traditional covering materials.

For customers whose transport routes involve coastal salt spray zones or chemical cargoes, we offer 316L stainless steel rope netting. 316L stainless steel rope netting offers enhanced corrosion resistance, effectively withstanding acid and alkali exposure to further extend service life. Additionally, stainless steel inherently possesses high tensile strength and toughness. It resists breakage and deformation under cargo compression, road vibration stress, or strong wind impacts, maintaining stable covering and protective performance over the long term.

Scientific Design, Combining Safety Protection & Practicality

1. Flexible mesh design accommodates various cargo types: Our stainless steel cargo net can be customized with mesh sizes according to customer requirements. For fine bulk goods like coal and sand, smaller mesh sizes prevent leakage during transit. For large items such as lumber and steel, larger mesh sizes ensure secure cargo retention while reducing wind resistance and lowering transportation energy consumption. The mesh structure also provides excellent ventilation, preventing mold growth from airtight conditions and minimizing water accumulation during rainy weather.

2. Superior weaving technique ensures exceptional durability. The stainless steel rope net employs a weaving process where each stainless steel wire is intertwined, creating secure, tightly knotted joints with no risk of loosening or detachment. The net edges are reinforced with stainless steel cord ropes and can be fitted with specialized connectors for quick installation onto truck beds. The stainless steel cargo net adapts effortlessly to any truck model, requiring no complex tools for installation and significantly streamlining pre-transportation preparation.

3. Lightweight and compact for reduced operational costs. The stainless steel rope net is lightweight and easy to handle, minimizing manual labor during loading and unloading. Its flexible design allows for folding and storage after use, occupying minimal space and facilitating convenient transport alongside the vehicle.

Highly Compliant, Meeting Global Shipping Standards

Different countries and regions impose strict compliance requirements for truck cargo coverage. Transportation authorities explicitly mandate the use of secure covering devices when transporting bulk goods to prevent cargo spillage and road safety incidents. Covering materials must also possess adequate weather resistance to withstand varying environmental conditions across different road sections.

Our stainless steel rope netting fully complies with Canadian transportation regulations: both tensile strength and anti-spillage performance meet local safety standards, while the mesh color (silver by default, customizable to black) offers excellent visual visibility. Furthermore, stainless steel is an eco-friendly material that is recyclable and reusable, aligning with global green transportation trends and helping clients enhance their corporate environmental image.

Typical Applications of Stainless Steel Cargo Net in Truck Transportation

Stainless steel rope nets, with their flexible adaptability and outstanding performance, find extensive applications in the trucking industry, covering diverse cargo types and transport environments:

Bulk Building Material Transportation

The demand for transporting building materials such as sand, gravel, cement, and steel is enormous. Covering bulk materials with stainless steel rope netting prevents sand and gravel leakage during transit caused by road vibrations (avoiding road contamination while reducing cargo loss) and protects materials from rainwater or snowmelt immersion (e.g., cement clumping when wet, steel rusting when exposed to moisture). For transporting oversized steel sections, custom-sized stainless steel rope netting combined with reinforcement straps ensures the steel remains secure and prevents shifting or falling during transit, safeguarding road safety.

Agricultural Product Transportation

Stainless steel rope netting is also suitable for covering cross-regional shipments of agricultural products like wheat, corn, and potatoes. Traditional canvas covers offer poor breathability, making agricultural products susceptible to mold growth due to high temperatures and humidity during transport. Stainless steel rope nets, however, provide excellent breathability, maintaining air circulation and effectively preventing spoilage. Additionally, stainless steel rope nets are non-toxic and odorless, posing no contamination risk to agricultural products and meeting food safety transportation requirements. During winter transport, stainless steel rope nets withstand severe cold without brittle fracture at low temperatures, ensuring the safety of agricultural products throughout the entire journey.

Transportation of Heavy Cargoes

Heavy cargoes possess high density and weight, demanding exceptional tensile strength and durability from covering materials. Ordinary plastic or nylon nets are prone to tearing or breaking during transport of such goods. Stainless steel rope netting, however, leverages its superior tensile strength and abrasion resistance to withstand the crushing pressure and friction of heavy loads, securely anchoring cargo to prevent shifting during transit. Additionally, stainless steel rope netting exhibits strong corrosion resistance, withstanding the acidic and alkaline substances present in coal and ore to extend its service life.

Coastal and High-Altitude Cold Region Transportation

In coastal areas with high salt fog concentration, traditional materials are prone to salt fog corrosion, significantly shortening their lifespan. Stainless steel rope netting (especially 316L grade) effectively resists salt fog erosion while maintaining excellent performance. In frigid regions, extreme winter temperatures cause ordinary plastic nets and canvas to become brittle, harden, and prove difficult to handle. Stainless steel rope netting retains excellent flexibility and strength in low temperatures, enabling easy installation and removal without compromising transportation efficiency due to weather conditions.

Our Stainless Steel Cargo Net: Quality & Service Guaranteed

Source Control, Reliable Quality

We operate a specialized stainless steel rope net production base, implementing standardized management throughout the entire process from raw material procurement to manufacturing. All raw materials are sourced from renowned stainless steel producers, with each batch accompanied by material inspection reports. Advanced weaving equipment and automated testing devices are employed during production to ensure every meter of rope net meets quality standards. Our products have obtained multiple authoritative certifications, including Quality Management System certification, corrosion resistance testing, and tensile strength testing, guaranteeing assured quality.

Customized Solutions, Precise Fit for Your Needs

We understand that truck types, cargo characteristics, and transport environments vary across clients. Therefore, we offer comprehensive customization services. Whether it’s mesh size, net dimensions, material selection, or connecting hardware, we tailor solutions to your specific requirements. Our technical team provides expert recommendations, matching your actual usage scenarios with the most suitable product solutions to ensure both functionality and cost-effectiveness.

Comprehensive After-Sales Support for Seamless Experience

From sample inquiries to product delivery and ongoing usage, we provide end-to-end after-sales support. For international clients, we offer logistics tracking and customs clearance assistance to ensure smooth delivery. Should installation or maintenance issues arise during product use, our technical team is available to provide guidance.

Conclusion

The shipment of stainless steel rope net samples to our Canadian client represents not merely a product demonstration, but a transmission of quality and the establishment of trust. In the field of truck cargo coverage, stainless steel rope nets are increasingly replacing traditional covering materials due to their core advantages: exceptional weather resistance, high durability, safety and reliability, and excellent compliance. They are emerging as a new choice for the global transportation industry.

We steadfastly uphold the business philosophy of “Quality First, Customer Foremost,” focusing on the R&D, production, and sales of stainless steel rope netting. We are committed to providing high-quality cargo covering solutions for global customers. Whether on Canada’s vast highways or transportation networks worldwide, we aim to enhance transport safety and efficiency while reducing operational costs through superior products and services.

If you are seeking reliable truck cargo covering solutions, we welcome your inquiry. We will provide customized product solutions and professional services to make your cargo transportation safer, more efficient, and more worry-free. We look forward to partnering with you—connecting the world through quality and building a future of mutual success through integrity!