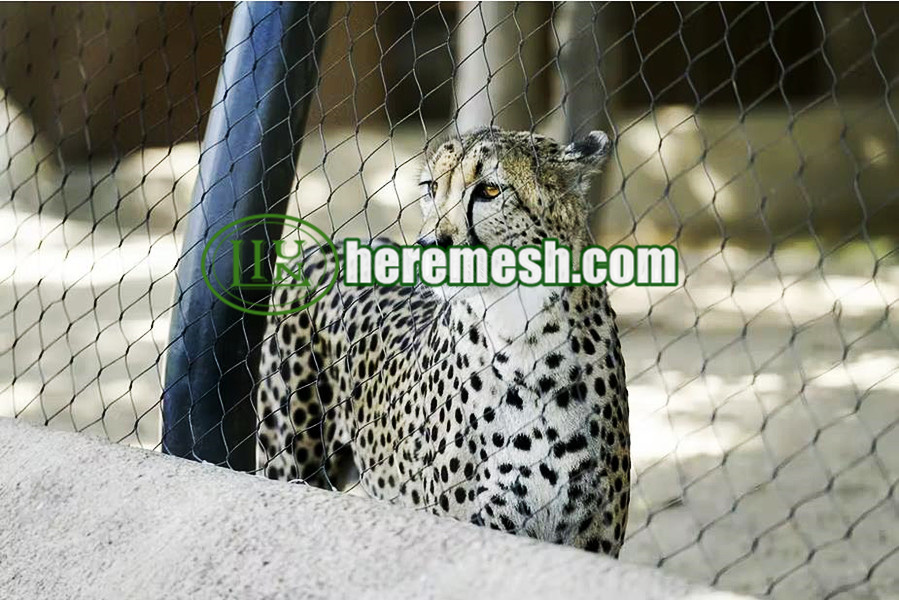

Clear View Flexible Cable Mesh for Animal Enclosures

Balancing Safety and Ecology: System Design of Tiger Exhibit Fence

10/17/2025

Black Cable Mesh Stadium Project: From Raw Materials to Delivery

10/30/2025In the planning and design of modern zoos, enhancing animal welfare has become a core priority for planners and managers. Consequently, animal enclosures have evolved beyond their earlier function of mere confinement to focus on comprehensively meeting animals’ natural behavioral and welfare needs. Within this transformation, the design philosophy and technical application of enclosure systems play a particularly crucial role. The once-ubiquitous steel-reinforced fencing is gradually being replaced by more adaptable, nature-inspired flexible animal enclosures.

Animal Enclosures Introduction

Animal enclosures (exhibition areas) form the core component of zoos. They serve not only as habitats for animals’ daily lives but also as primary channels for visitors to observe and understand wildlife, thereby fostering conservation awareness. An excellent enclosure design must balance multiple objectives:

Animal Welfare: Ensuring animals have sufficient space to engage in natural behaviors such as running, climbing, foraging, socializing, and resting. The environment must be enriched and diverse to meet their physiological and psychological needs.

Visitor Experience: Providing barrier-free, clear, and immersive viewing perspectives that allow visitors to safely observe natural animal behaviors while delivering educational and entertaining experiences.

Safety Assurance: This is the most fundamental and critical requirement. Animal enclosures must be absolutely reliable, effectively containing animals to prevent escape while safeguarding visitors and staff.

Durability and Aesthetics: Enclosure structures must withstand harsh weather and animal damage. Their appearance should blend naturally and discreetly with the surrounding landscape, avoiding jarring contrasts.

Traditional enclosures, such as solid iron bars or dense wire mesh, often create a conflict between safety and animal welfare. While sturdy, they obstruct views, limit ventilation and natural light, causing psychological stress to animals and detracting from the visitor experience. Flexible animal enclosures netting solutions were developed precisely to resolve this dilemma.

What is Flexible Animal Enclosures Mesh?

“Flexible animal enclosures mesh” does not imply structural weakness or instability, but rather refers to its high adaptability and transparency in design, form, and function. It is a mesh structure primarily composed of high-performance stainless steel materials, manufactured through specific weaving or connecting processes.

Its core “flexible” characteristics are manifested in the following aspects:

Visual Transparency: The mesh structure minimizes visual barriers, offering visitors nearly unobstructed viewing while providing animals with broader vistas and reduced feelings of confinement.

Structural Adaptability: This mesh structure effortlessly adapts to complex terrains and architectural designs. Whether spanning ravines, covering domes, or enveloping irregular structures, flexible animal enclosures netting achieves a perfect fit. It can be engineered into flat, curved, arched, or any other form.

Physical Flexibility: Unlike rigid structures, flexible netting possesses inherent cushioning properties. When animals—particularly large or agile species like primates or leopards—collide with the enclosure, the mesh undergoes slight deformation to absorb impact energy. This reduces injury risk to animals while simultaneously lowering structural stress loads.

Functional Integration: It seamlessly integrates with environmental enrichment elements like vegetation, rockeries, and water sources, forming an ecological barrier that achieves an “invisible” boundary effect.

Stainless steel woven mesh and stainless steel ferrule mesh are the two primary technical forms used to construct this flexible enclosure system.

The Type of Flexible Cable Mesh

Within the realm of flexible enclosure netting, two primary types exist, each with distinct characteristics suited for different scenarios.

Stainless Steel Cable Mesh

Stainless steel cable mesh is formed by hand-weaving high-strength stainless steel cables into an integrated grid structure.

Exceptional Strength and Resilience: Individual cables withstand tensile forces of several tons to dozens of tons, with the overall structure capable of absorbing significant impacts.

Superior Transparency: Mesh apertures can be adjusted for openness, typically offering greater visual clarity than ferrule mesh panels with minimal visual disruption, achieving an invisible viewing effect.

Elegant Aesthetics: Sleek lines and minimalist structure deliver a distinctly modern look, seamlessly integrating into high-end, contemporary zoo designs.

Exceptional Corrosion Resistance: AISI 316-grade stainless steel withstands marine climates and zoo environments, ensuring an exceptionally long service life.

Large Carnivores: Ideal for high-strength, high-security enclosures housing lions, tigers, leopards, wolves, and similar species.

Bird Flight Enclosures: The preferred choice for large avian nets, providing ample flight space while maintaining visitor visibility.

Primates: Provides challenging climbing structures for gorillas, monkeys, and other agile climbers while ensuring safety.

Aquatic Enclosures: Used for waterfowl, crocodiles, and other aquatic animals, offering resistance to water erosion.

Stainless Steel Ferrule Mesh

Stainless steel ferrule mesh is formed by securing stainless steel wires at each intersection using ferrules, creating a grid pattern. It offers slightly greater overall rigidity than rope netting while retaining flexibility.

Uniform Mesh Distribution: Typically diamond-shaped for a neat, aesthetic appearance.

Excellent Shear Resistance: Thicker wire diameter and secure joints effectively prevent animals from tearing or biting through.

Versatility: Suitable as primary fencing, partitioning, protective barriers, or decorative screens.

Cost-effectiveness and Practicality: Ferrule mesh offers advantages in scenarios requiring smaller mesh sizes to prevent small animals from escaping.

Small to Medium Mammals: Such as foxes, red pandas, etc.

Reptile Exhibits: For overhead protection or separation within display areas.

Children’s Zoos: For separating docile herbivores, offering high safety and aesthetic appeal.

Benefits of Flexible Animal Enclosures Mesh

The benefits of choosing stainless steel rope netting or ferrule netting are multifaceted, impacting every aspect of zoo operations.

For Animals:

Enhanced animal welfare: Expanded views and natural light reduce the occurrence of stereotypical behaviors. The flexible structure lowers the risk of injury from collisions. The netting itself can serve as part of environmental enrichment, providing opportunities for animals to climb and explore.

Simulates natural habitats: Nearly invisible boundaries create the sensation of living in broader, freer spaces, encouraging animals to express their natural behaviors.

For Visitors:

Immersive viewing experience: Gone are the days of viewing through bars. Visitors can clearly capture every detail of animals through the mesh—whether through camera lenses or the naked eye—enjoying a more engaging and memorable visit.

Safety Assurance: Though appearing lightweight, its strength far exceeds expectations, providing a solid and reliable safety barrier for visitors.

Educational and Aesthetic Value: This advanced design itself serves as an exhibit, showcasing modern zoos’ progress in technology and animal welfare to visitors.

For Zoo Management:

Extended Lifespan and Low Maintenance: Stainless steel requires minimal upkeep, resisting corrosion, fading, and aging. This significantly reduces routine maintenance, repainting, and replacement frequency and costs.

Exceptional Durability: Withstands diverse climatic conditions and withstands scratching and gnawing from most animals.

Design and construction flexibility: Customizable to any size, shape, and mesh specification, offering designers unlimited creative possibilities and enabling complex structures unattainable with traditional materials.

Overall cost-effectiveness: While the initial investment may be higher, its decades-long lifespan and virtually zero maintenance expenses result in a significantly lower total cost of ownership compared to many traditional materials over its entire lifecycle.

Design a Flexible Animal Enclosure Netting

Designing a successful flexible enclosure is a systematic engineering project requiring collaboration among multiple professionals.

1. Requirement Analysis and Species Assessment:

The primary step involves gaining a thorough understanding of the animals within the enclosure: including their species, body size, weight, jumping ability, climbing skills, bite force, behavioral habits, etc. For instance, designing a leopard enclosure necessitates accounting for its remarkable leaping and climbing abilities. Conversely, a bear enclosure must prioritize evaluating its immense strength and destructive potential.

2. Structural Engineering Calculations:

This forms the core of safety. Structural engineers must perform calculations based on the animal’s impact force, wind loads, snow loads, and the net’s own weight.

Key parameters include: stainless steel cable diameter, mesh size (preventing animal entrapment while ensuring visibility), and breaking strength.

Boundary Anchoring System Design: Securely anchoring the enclosure’s perimeter is critical. This requires robust support structures (e.g., steel columns, concrete beams) and specialized fasteners to effectively transmit and distribute impact forces.

3. Aesthetic and Landscape Integration Design:

Landscape architects and designers must skillfully “conceal” the net structure within the environment. Examples include camouflaging support columns as tree trunks, planting climbing vines around the net, or utilizing terrain elevation to position the net below visitor sightlines. Select net colors (typically stainless steel’s natural finish or black) to blend seamlessly with the backdrop.

4. Detailed Considerations:

Anti-Climbing Measures: For primates and similar animals, anti-climb panels may need to be installed on support columns.

Ground Sealing: The junction between the net structure and the ground requires specialized treatment to prevent animals from digging their way out. This is typically achieved using concrete foundations or downward-extending mesh panels.

Access Control System: All gates leading into the enclosure must incorporate security designs of equivalent standards and be equipped with multiple locking mechanisms.

Install a Flexible Animal Enclosure Netting

Professional installation is the ultimate guarantee for realizing design intent and safety performance.

1. Preparatory Work:

Site Survey and Foundation Construction: Strictly follow design drawings during construction to ensure precise positioning, leveling, and structural integrity.

Material Inspection: All delivered stainless steel rope nets, clips, fasteners, and other components must undergo quality checks to confirm compliance with specifications.

2. Installation Process:

Support Structure Installation: Position and align steel columns, main beams, and other supporting structures.

Net Unfolding and Preliminary Fixing: Carefully unroll the net from its coiled state using specialized tools and equipment, avoiding twists. Temporarily secure one end of the net to the support structure.

Tensioning and Adjustment: This is the most critical step. Use tools to sequentially tension the net to the design-specified tension. This process must be performed slowly and synchronously to ensure uniform stress distribution across the entire net surface, achieving the desired flatness and rigidity. For stainless steel rope nets, individually inspect the security of each clamp connection.

Final Fixing and Trimming: Once tension reaches design values, permanently secure the net using fixtures and bolts. Trim away excess material.

Detailing: Install anti-climb features, door locks, etc.

3. Testing and Acceptance:

After installation, conduct a comprehensive safety inspection. This includes visual checks of all connection points and potential simulated impact tests to verify the enclosure’s overall performance.

Conclusion

Stainless steel cable mesh and ferrule mesh represent flexible enclosure solutions for zoos, an inevitable evolution of modern zoo philosophy. With exceptional safety, near-invisible transparency, extraordinary durability, and limitless design potential, they successfully foster harmony among animals, visitors, and management. More than just a physical barrier, they serve as a bridge connecting humanity and the natural world, enabling conservation, education, and appreciation to unfold in a more natural and humane manner. Investing in such advanced enclosure systems is investing in the future of zoos—a future that prioritizes animal welfare, enhances visitor engagement, and ensures sustainable operations.

Email: [email protected]/[email protected]

FACEBOOK——Liulin Metal Fabric Co.,Ltd