Quick-Install Ferrule-Type Staircase Mesh – Ship to Switzerland

Premium China Metal Rope Mesh Manufacturers – Custom Solutions

12/11/2025

Season’s Greetings From Your Partner Liulin Zoo Mesh Factory

12/23/2025Mesh Sample Shipped to Switzerland

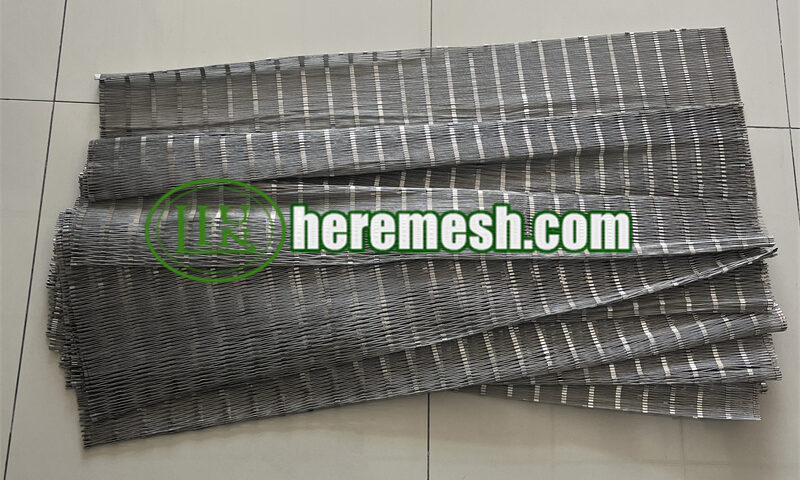

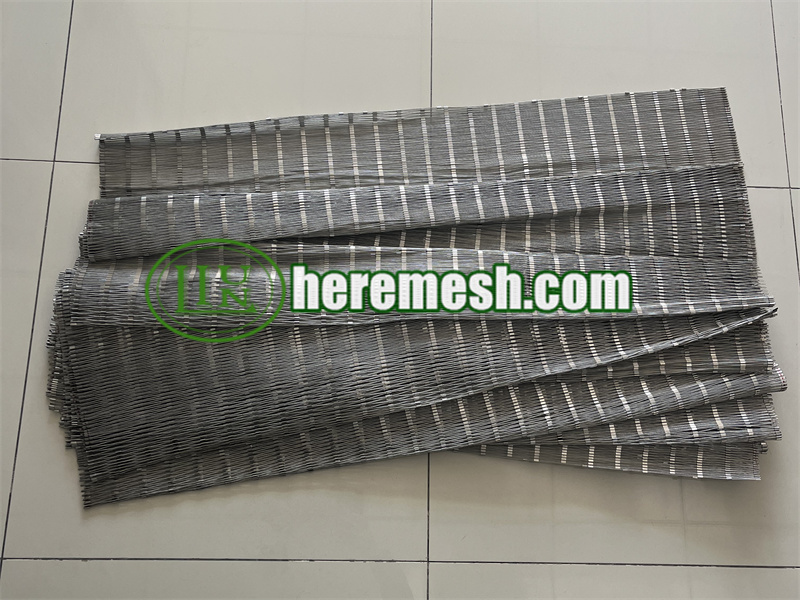

We have already shipped ferrule-type staircase mesh to Switzerland this month. This sample will be used in their staircase protection system. This marks a significant step forward in our expansion into the high-end architectural safety materials market in Europe.

The user initially reached out to us through our company website, expressing a clear need for a robust, reliable, and easy-to-install guard solution for the staircases of their new construction project in Switzerland. Upon receiving the inquiry, we promptly established direct and efficient communication via email.

Through in-depth discussions, we learned the user placed high priority on the product’s load-bearing capacity, durability and ease of installation. Based on these requirements, our technical team ultimately recommended the Model 1240 ferrule type mesh for the staircase application.

Our recommendation was based on three key factors. First, its unique ferrule design enables rapid, secure on-site installation without complex welding or specialized tools, significantly reducing labor time and costs. Second, crafted from premium stainless steel, it delivers exceptional corrosion resistance and load-bearing capacity, fully adapting to Switzerland’s climate while meeting long-term safety requirements. Third, the 1240 model’s mesh specifications and structural design achieve an optimal balance between transparency and protection, aligning with modern architectural aesthetics and safety standards.

The meticulously prepared samples have now been formally dispatched. We are confident this product will perfectly meet the project requirements. We will continue to provide comprehensive technical support to ensure the smooth progress of the user’s project.

Introduction to the Ferrule-Type Staircase Mesh

In modern architectural design, staircases serve not only as passageways connecting different floors but also as critical escape routes and safety nodes during emergencies. Consequently, the safety and reliability of their protective installations are paramount. Traditional staircase protection solutions, such as welded railings or fixed gratings, while meeting basic safety requirements, often suffer from drawbacks like time-consuming installation, limited flexibility, and complex maintenance.

The advent of stainless steel ferrule mesh represents an engineering innovation addressing these very challenges. It is not merely a material substitution. Its core lies in a unique ferrule connection system that eliminates the need for on-site welding. This flexible mesh enables rapid, precise installation. Once installed, the staircase forms a high-strength, highly stable protective surface. This design delivers not only a leap in installation efficiency but also a comprehensive enhancement in safety performance:

Immediate Protection:

Ferrule type mesh drastically shortens construction cycles, enabling faster deployment of the protection system. This is particularly valuable for renovation projects or new constructions with tight schedules, allowing early mitigation of fall hazards.

Sturdy Connections:

Each ferrule ensures uniform, reliable force distribution between the mesh and supporting structure. Its impact and lateral load resistance meet stringent safety standards, providing round-the-clock passive protection.

Transparent Visibility:

Exceptional transparency preserves natural light and unobstructed sightlines in staircases. Ferrule-type staircase mesh eliminates visual oppression. Moreover, it aligns with modern architecture’s dual pursuit of functionality and aesthetics.

Adaptable for Complex Environments:

High-grade stainless steel delivers exceptional corrosion and weather resistance. This performance effortlessly handles Switzerland’s diverse climates and potential stairwell humidity, ensuring structural integrity over extended use.

Selecting stainless steel ferrule mesh as a stairwell safety solution fundamentally represents choosing a more efficient and reliable approach to safety management. Choosing stainless steel sleeve mesh is a safety solution for stairIt fundamentally represents selecting a more effective management method.It serves not only as a protective barrier but also as a responsive, robust, and durable intelligent module within the building’s safety system. The Model 1240 sample shipped to the user embodies this advanced concept, delivering a proven, superior solution for their project.

The Function of the Ferrule-Type Staircase Mesh

The quick-install safety mesh is specially designed for the unique space of staircases. Its function goes far beyond mere obstruction. Through a systematic solution, it meets the various comprehensive demands of modern buildings for the stair area. Its main functions can be summarized as follows:

Core Safety Protection, Preventing Accidental Falls

Personnel fall prevention: This is the most fundamental and crucial function. It provides reliable side protection for open staircases, rotating staircases, and mezzanine staircases, effectively preventing people from accidentally slipping and falling from the gaps between the stair railings or the sides, thus avoiding serious injuries.

Item fall prevention: Prevent small items such as mobile phones, toys, and tools from falling from the gaps between the stair railings. This avoids injuring people below or causing property damage, and also reduces the safety risks of falling objects from heights.

Space Optimization and Visual Management

Combining transparency and safety: The metal mesh itself has excellent transparency and does not completely block vision and light like solid plates. This enables the staircase space to achieve safety while maintaining an open and coherent feel, avoiding a sense of oppression. The ferrule-type staircase mesh is particularly suitable for residential and commercial spaces with poor lighting or those seeking an open visual effect.

Defining and beautifying the space: The simple and modern texture formed by the mesh surface becomes a decorative element in itself. It can softly define the boundaries of the staircase area, enhance the overall design sense, and transform the staircase from a simple transportation passage into an integral part of architectural aesthetics.

Physical and Psychological Protection

Wind prevention and microclimate regulation: For stairs located near the entrance or atrium, a certain density of mesh surface can effectively slow down air convection, providing a certain wind prevention effect and enhancing the comfort of the users when going up and down the stairs.

Anxiety relief for those with acrophobia: For glass railings on stairs with a high floor height or excessive transparency, adding a layer of solid and textured protective net can provide important visual and psychological support for users with acrophobia, increasing their sense of security.

Easy Installation and Flexible Adaptation

Special design for stairs: The “ferrule-type” installation method is particularly suitable for the complex structure of stairs with multiple angles and nodes. No large-scale welding or damage to the original structure is required. Usually, it can be quickly installed on the columns, handrails or sides of the stairs through special clamps, fasteners, etc., significantly shortening the construction time and reducing dust and noise pollution.

Adapts to various existing stair renovations: Whether it is a metal, wooden or concrete-structured staircase, the ferrule-type design can usually be added through compatible installation components, making it an ideal choice for upgrading floor safety or functional renovations. The material of the ferrule-type staircase mesh is stainless steel. It has the characteristics of corrosion resistance and impact resistance, and does not require frequent maintenance during long-term use, with low life cycle cost.

The Main Features of High-quality Ferrule-Type Staircase Mesh

High-quality staircase protection nets differ from ordinary safety nets in that they not only meet basic safety requirements but also pursue excellence in durability, reliability, aesthetics, and user-friendly design. Their core characteristics can be summarized as follows:

Superior Materials and Structure

Stainless Steel Wire: It utilizes high-grade stainless steel wire (e.g., 316 or 304) with exceptional corrosion and rust resistance, ensuring long-term performance in humid, acidic, or alkaline environments.

Fittings: All ferrules and connectors are crafted from premium stainless steel matching or compatible with the mesh wire, eliminating electrochemical corrosion and guaranteeing structural integrity.

Secure Knots: Precision weaving techniques ensure each intersection is robust and uniform, preventing mesh deformation under stress and enabling even energy distribution.

Edge Treatment: Mesh edges are reinforced with specialized ferrules rather than simple cutting—a critical measure to prevent fraying and maintain structural integrity.

Professional Engineering Design

High Break Strength: Both individual filament strength and overall mesh break strength far exceed conventional safety standards, capable of withstanding sudden high-impact loads (simulating human fall impacts).

Strong Fatigue Resistance: Under prolonged exposure to wind, rain, vibration, or cyclic pressure, the mesh resists metal fatigue that could degrade performance.

Human-Centered Safety Details

Smooth: All exposed joints and edges undergo smoothing treatment, ensuring a smooth texture and completely eliminating the risk of hand lacerations during installation or use.

Consistent Mesh Aperture: Uniform apertures with precisely calculated dimensions guarantee excellent visibility while effectively preventing children’s heads from passing through or becoming trapped.

Efficient and Convenient Installation System

Modular Design: Mesh panels assemble on-site with basic tools, significantly reducing installation time and minimizing field fabrication errors.

Adaptive Connections: Flexible snap-fit mechanisms securely accommodate various common post shapes (round, square) and sizes, facilitating retrofits for diverse existing stair structures.

Secure and Reliable Connections

Rigid Fixation: High-quality clips deliver strong locking force and anti-twist capability, ensuring no swaying or rattling after installation for a solid protective feel.

Easy Maintenance and Removal: The superior design guarantees firmness while allowing non-destructive disassembly when necessary, facilitating maintenance of the staircase structure or mesh panels.

Long-lasting Aesthetics and Low Maintenance

Premium Finish: Available in natural metal or surface-treated finishes, the mesh embodies modern industrial aesthetics while maintaining a fresh appearance over time.

Self-cleaning: The open mesh structure resists dust and debris accumulation, requiring only rainwater to maintain cleanliness with minimal upkeep.

Long-Term Durability and Cost-Effectiveness

Low lifecycle cost: While the initial investment may be higher, its exceptionally long service life (lasting decades) and near-zero maintenance costs deliver superior long-term economic benefits compared to low-quality products requiring frequent replacement or upkeep.

Corrosion Protection Guarantee: High-quality materials and craftsmanship provide long-term rust and corrosion resistance, representing a “once-and-for-all” safe investment.

The core characteristics of high-quality ferrule-type staircase mesh are: Ensuring intrinsic safety through premium materials and precision manufacturing. Enhancing user experience with ergonomic design and rapid installation systems. Achieving the lowest total lifecycle cost through enduring performance. It is not merely a safety barrier but a building component embodying professional value and reliable quality.

Conclusion

We have discovered that the rapid installation of the ferrule mesh is no longer merely a simple safety protection product. Instead, it has become an integrated solution in modern architectural design that combines functionality, aesthetics, and engineering wisdom.

It precisely responds to the triple demands of contemporary spaces for safety, openness, and efficiency: with an impregnable metal mesh to safeguard absolute safety for lives, with a transparent and light visual language to respect the aesthetic expression of the building, and with the ingenious design of snap connections to transform the complex installation process into a simple and efficient on-site assembly. Behind this, there is a deep integration of material science, structural mechanics, and humanized design.

Choosing a high-quality ferrule-type staircase mesh is essentially an investment in long-term value and ultimate reliability. It means solving safety hazards once and for all, without having to repeatedly maintain for rust, loosening in the future. The mesh body on the metal surface injects a timeless modern texture into the building, making it appear more upscale. Looking to the future, as building regulations continue to improve and people’s pursuit of living quality keeps rising, this product that hides safety in plain sight and transforms protection into art will undoubtedly become the best choice for connecting spaces and safeguarding human safety.