Stainless steel netting in modern architecture and industry

Safe and Durable Zoo Enclosures

06/12/2025

Safety and Aesthetic Integration in Modern Zoo Tunnel Mesh

06/20/2025This article comprehensively discusses the wide application of stainless steel netting and its multifunctional properties in modern architecture and industry. Stainless steel netting has become an important material in the fields of architectural decoration, safety protection and industrial filtration by virtue of its excellent corrosion resistance, high strength, aesthetics and environmental protection characteristics. The article analyzes in detail the material properties, production process, application scenarios and customized production of stainless steel mesh. Stainless steel mesh provides technical reference and application guidance for related industries. The study shows that stainless steel mesh can achieve aesthetic value while meeting functional needs. And its future development will focus more on environmental protection.

Stainless steel netting material properties and production process

Stainless steel mesh is used as a high performance metal mesh material. This material has been widely used in many fields in recent years, such as construction, industry, zoo and so on. With the continuous improvement of the material performance requirements of modern construction, stainless steel mesh is gradually replacing the traditional metal mesh material by virtue of its unique performance advantages. Stainless steel mesh has become one of the preferred functional materials in various industries.

Corrosion resistance

The core value of stainless steel mesh is firstly reflected in its excellent material properties. As an alloy material, stainless steel is mainly composed of iron, chromium, nickel and other elements, of which the chromium content is usually not less than 10.5%, which is the key to the formation of its corrosion resistance. Chromium can form a layer of dense chromium oxide protective film on the surface of the material, effectively isolating the erosion of oxygen and moisture on the substrate. In addition, by adjusting the content of nickel, molybdenum and other alloying elements, the acid and alkali resistance, high temperature resistance and mechanical strength of stainless steel mesh can be further enhanced.

Production process

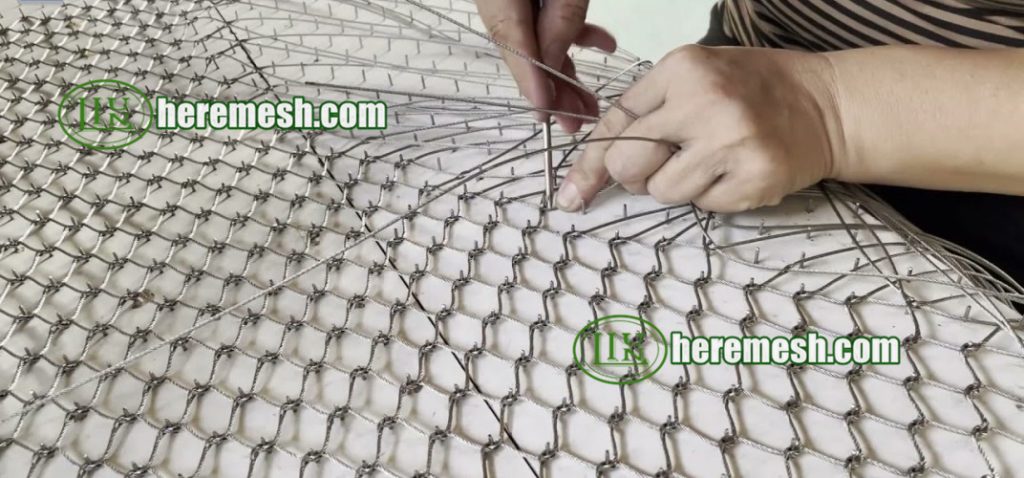

From the perspective of production process, the manufacturing process of integrates traditional metal processing and modern precision manufacturing technology. The main production process includes weaving process and ferrule process. The weaving process forms a mesh structure by interlacing steel wires. And the mesh aperture and wire diameter can be adjusted according to the needs. The ferrule process is usually formed by weaving stainless steel wires and fixed by a ferrule design. Each process has its own unique advantages and application scenarios. Stainless steel woven mesh is flexible and suitable for curved surfaces. Ferrule mesh is easy to install and dismantle quickly, and the design is aesthetically pleasing.

Surface treatment

The surface treatment technology of stainless steel mesh is also extremely important. The oxidized treatment not only enhances the corrosion resistance of the product, but also gives it a unique aesthetic effect. For example, black oxidized stainless steel netting can reduce reflection, suitable for creating a strong sense of modern building facade. Black oxidized treatment can present advanced, more suitable for creating low-key luxury outdoor space atmosphere.

Innovative applications of stainless steel netting in construction

Architectural outdoor design: plasticity and creativity

In contemporary architectural design, stainless steel netting has been transformed from a purely functional material into an architectural element with both practical and aesthetic values. As a facade material, stainless steel mesh can effectively regulate light and sight lines while maintaining good ventilation. Its unique metallic texture and plasticity provide architects with a wide range of creative space. For example, three-dimensional stainless steel mesh made through a special weaving process can form a shaped design effect. Flexible products present different visual experiences.

Interior design: transparency and functionality

In the field of interior design, the application of stainless steel netting is equally colorful. It can be used as a space partition, which can divide the functional area, but will not completely block the line of sight and light flow. This mesh material is particularly suitable for open plan office spaces and commercial premises. As a ceiling decorative material, stainless steel netting can hide piping and equipment while maintaining a sense of transparency at the top. Stainless steel mesh is also widely used in stair railings, wall finishes, and other areas where its durability and easy-to-clean characteristics make it particularly suitable for high-traffic areas.

Landscaping design: artistry and ecology

Landscaping is another important area of stainless steel mesh application. In parks, squares and other outdoor spaces, stainless steel mesh can be made into a variety of art installations, resting pavilions, fences and so on. Its weather resistance ensures that it is not easy to age and discolor in long-term use. Stainless steel netting systems combined with greenery are even more common solutions for modern vertical gardens. The mesh provides a support structure without interfering with plant growth. Stainless steel mesh is increasingly being used in architectural shading systems. With precisely calculated mesh density, ideal shading and heat blocking effects can be achieved while maintaining a clear view.

The key role of stainless steel mesh in industry

Stainless steel rope mesh plays an important protective and safety role in industry. Its high strength and corrosion-resistant properties make it the material of choice for heavy equipment protection, safety nets for work at height, and hazardous area isolation. In factory workshops or construction sites, stainless steel rope netting can effectively block falling objects or accidental ejection of mechanical parts, reducing the risk of work-related injuries. Its impact resistance can absorb energy and reduce the damage caused by accidents, ensuring a safe and stable working environment.

Stainless steel netting performs well in harsh environments such as petrochemical and marine engineering. Stainless steel rope mesh has become a key facility for pipeline protection, platform fencing and tank farm isolation by virtue of its excellent resistance to acid and alkali and salt spray corrosion. It is able to resist the erosion of chemical media. It can maintain long-term structural stability under high temperature and high humidity conditions, avoiding safety hazards caused by material aging. In addition, the light and air permeability of the rope mesh helps to maintain the ventilation and heat dissipation of the equipment, preventing localized overheating, thereby enhancing the reliability of the overall industrial system.

Stainless steel rope mesh also plays an important role in logistics, transportation and warehousing, such as cargo securing, sorting isolation and lifting protection. Its lightweight design reduces structural loads, while its high load capacity withstands the crush and friction of heavy cargo. In automated production lines or smart warehouses, the flexibility and customizability of rope nets allow them to be adapted to different shapes and sizes of goods management needs, increasing operational efficiency and reducing wastage. This combination of functionality and economy makes them an indispensable component in the optimization of modern industrial processes.

Stainless steel netting safety protection and environmental protection value

Safety protection is the traditional application field of stainless steel mesh, but its technical connotation is constantly upgrading. Protection nets for bridges, fencing nets for stadiums and zoos, all require both high strength and durability. Modern stainless steel safety protection nets commonly use special weaving process, the overall structure can still remain intact, greatly improving the safety and reliability. Stainless steel mesh meets the requirements of different protection levels.

In terms of environmental protection, stainless steel mesh sustainability shows obvious advantages. First of all, stainless steel mesh has an extremely long service life, much higher than ordinary metal mesh. The long service life reduces the frequency of material replacement and resource consumption. Secondly, stainless steel mesh is 100% recyclable and the recycling process has low energy consumption, which is in line with the concept of circular economy. These characteristics make stainless steel mesh the preferred material in the environmental protection building certification system.

Stainless steel rope mesh is the preferred material for animal enclosures due to its high strength, corrosion resistance and flexibility. Stainless steel rope mesh is able to withstand the impact of large animals, such as lions, tigers, bears and other fierce beasts to tear and climb. At the same time, the soft mesh body avoids animals from being injured due to the collision of hard fences. The flexible structure can cushion the impact and reduce the risk of animal escape or accidental injury.

In addition, the rope mesh has excellent UV and rust resistance, and will not corrode or become brittle even when exposed to outdoor humidity for a long period of time. This feature guarantees long-term reliability. Its transparent design not only meets the zoo’s natural landscape needs and reduces visual obstruction, but also maintains good ventilation and lighting, providing a more comfortable habitat for animals.

Customized production of stainless steel mesh

With the diversification of modern architectural and industrial needs, the customized production of stainless steel mesh has become the key to meet the application of specific scenarios. Stainless steel wire mesh can be precisely customized in terms of mesh size, wire diameter, and surface treatment. Customized production of stainless steel mesh ensures optimal performance in terms of strength, light transmission, air permeability or decorative properties. For example, architectural curtain walls can be customized with large apertures for decorative openings. Zoo fences can be customized with thick rope diameters for impact resistance. The perfect mesh is integrated into the aesthetic and functional requirements of modern architecture, providing users with diversified choices. Customized production not only improves the applicability and efficiency of stainless steel mesh, but also promotes its innovative application in high-end fields.

Conclusion

As a multifunctional engineering material, stainless steel mesh has been deeply integrated into various fields of modern construction and industrial production. Its unique performance advantages not only solve many engineering technical problems, but also provide designers with a wealth of creative elements. With the continuous accumulation of application practice and continuous innovation of manufacturing technology, stainless steel mesh will certainly show its value in more fields. The future development of stainless steel mesh will pay more attention to the balance between performance optimization and environmental friendliness. Customized mesh creates a safer, more beautiful and more sustainable built environment for mankind.