Premium Stainless Steel Hand Woven Multiple Wire Mesh

Safety and Aesthetic Integration in Modern Zoo Tunnel Mesh

06/20/2025

Order Delivery to US: Selection of Outdoor Bird Netting

07/03/2025Stainless steel hand woven multiple wire mesh is a kind of metal product with both practicality and artistry. Hand woven multiple wire mesh plays an important role in modern architectural decoration, safety protection, home design and other fields. Its unique weaving process, excellent material properties and wide range of applications make it an important category in the metal mesh industry. This article will comprehensively explain the concept, advantages and common specifications of stainless steel hand-woven wire mesh. Through an in-depth discussion of product performance is conducive to the user to understand the value of this product.

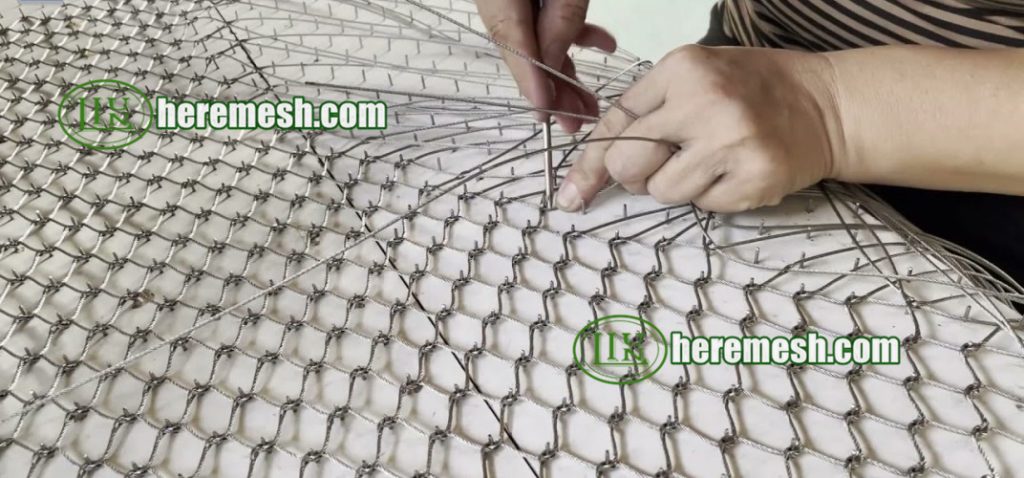

1. Introduction to Hand Woven Multiple Wire Mesh

Hand woven multiple wire mesh is a mesh structure product made of high-quality stainless steel wire woven by hand. (Such as 304, 316 and other materials) The production process usually involves several stages. Each step is carefully handled to ensure the strength, flexibility and aesthetics of the final product. Compared with mechanical weaving, hand-woven mesh has more advantages in terms of flexibility, fineness and artistic expression. Hand woven multiple wire mesh is capable of more complex patterns and textures.

Hand-woven mesh is aesthetically pleasing and the X-shaped cross-woven mesh is suitable for most conventional applications. The simplicity of a woven mesh enhances the visual hierarchy. The patterned surface of the multi-stranded wire is more decorative and suitable for indoor and outdoor decoration as well as high-end decoration.

Stainless steel hand woven multiple wire mesh not only has the strong and durable characteristics of metal material, but also can present rich artistic effects through different weaving techniques. Therefore, it is highly favored in the fields of modern architecture, interior design, landscape decoration and safety protection.

2. Key Advantages of Hand Woven Multiple Wire Mesh

2.1 Corrosion resistance of hand-woven mesh

Stainless steel gives hand-woven mesh excellent corrosion and oxidation resistance. 304 stainless steel is stable in regular environments. 316 stainless steel is suitable for marine environments or highly corrosive places. While 316 stainless steel is suitable for marine environments or highly corrosive places. 316 material is more corrosion-resistant, can keep the surface clean for a long time, not easy to rust or discoloration. This characteristic makes it has irreplaceable advantages in outdoor construction, chemical equipment, marine engineering and other fields.

2.2 Flexibility of hand-woven mesh

In the design and application of zoos, the flexibility and plasticity of hand-woven mesh show great advantages. Compared with the mechanical woven mesh, the hand-woven process can flexibly adjust the mesh size, weaving density and overall structural strength according to different animal habits and safety requirements. For example, in the design of enclosures for fierce animal areas, thicker stainless steel wires (over 3mm) and high-density weaving can be used to ensure that the mesh surface has sufficient impact resistance. The high-strength wire mesh prevents large animals such as lions and tigers from damaging it. While in the bird exhibition area, finer wire diameter (about 1.2mm) and medium aperture (20mm-30mm) can be used. This design ensures ventilation and light transmission, and prevents birds from escaping.

In addition, hand woven multiple wire mesh can be adapted to complex curved surfaces and shaped structures in zoos. For example, curved ornamental corridors or domed birdhouses are seamlessly fitted through customized weaving, which meets functional requirements and enhances the overall aesthetics. In the wildlife exhibits, the rope netting blends in with the natural environment, providing a safer and more immersive viewing experience for visitors.

2.3 Good light transmission and ventilation

Stainless steel hand woven multiple wire mesh also offers good light transmission and ventilation. Its mesh structure allows light and air to penetrate freely. It can ensure light and maintain air circulation in building facades or interior partitions. This characteristic makes it popular in commercial spaces, hotels, exhibition halls and other venues. In zoo venues, excellent light transmission and ventilation provide important advantages for the creation of animal habitats. This characteristic is particularly suitable for primate houses, aviaries and other display areas that require sufficient natural light. The hand-woven mesh allows 80-90% of sunlight to penetrate, providing animals with near-natural lighting conditions, which contributes to their healthy growth. At the same time, the evenly distributed holes on the mesh surface ensure the free flow of air, effectively preventing the accumulation of moisture in the pavilion and reducing the risk of respiratory diseases.

2.4 Simple and generous mesh structure

From an aesthetic point of view, hand woven multiple wire mesh is able to present a rich visual effect through the hand-woven method, wire thickness and surface treatment. Hand-woven wire mesh can be customized to fit perfectly into the overall environment and enhance the texture of the space.

Finally, the durability and low maintenance of stainless steel hand-woven mesh are also important advantages. Stainless steel material itself has a high strength, can withstand a certain degree of external impact, and the daily cleaning and maintenance is simple, only need to regularly wipe with water or neutral detergent can be maintained for a long time as new, greatly reducing the long-term cost of use.

3. Design Flexibility and Customization Options

Stainless steel hand-woven mesh is able to meet the functional and aesthetic needs of different scenarios thanks to its superior process adaptability and diverse customization capabilities. Whether it is a complex architectural decoration, a secure animal enclosure, or a unique art installation, the desired effect can be achieved through flexible weaving techniques and customized designs.

The hand-woven mesh can present rich visual layers and artistic expression through different weaving techniques and snap designs. The simple and generous mesh structure can enhance the transparency of the decorative space. By adjusting the weaving density and node processing, it can meet the needs of personalized design. Users can choose woven mesh or ferrule type mesh according to style preference.

Customization of stainless steel rope mesh is not only limited to appearance, but also optimizes the performance parameters for specific usage scenarios, ensuring a perfect balance between functionality and safety. Through precise customized design, stainless steel hand-woven wire mesh can achieve structural safety, visual aesthetics and environmental adaptability at the same time, making it an ideal solution for cross-discipline applications.

4. Common specifications of stainless steel hand woven multiple wire mesh

Stainless steel hand-woven wire mesh comes in a variety of sizes, usually differentiated by wire diameter, mesh size, weaving method and material.

In terms of wire diameter, the common stainless steel wire diameter ranges from 1.2mm to 3.2mm. The finer wire diameter is suitable for making fine decorative mesh with light visual effect. Medium wire diameter is suitable for architectural curtain walls, partitions, etc., balancing strength and aesthetics. The thicker diameters are used for security areas.

The size of the mesh varies according to the application, usually ranging from 20mm to 100mm. Small mesh is used for small bird protection. Medium mesh is commonly used for architectural decoration, balancing light transmission with shading. Large mesh (above 30mm) is mostly used for art installations or places with high ventilation requirements.

In terms of material selection, 304 stainless steel is the most commonly used model with good corrosion resistance and cost effectiveness. 316 stainless steel is suitable for highly corrosive environments such as coastal areas or chemical facilities. In addition, 304 stainless steel is an economical option for most environments. The surface treatment will also affect the final use of the effect. Users can choose whether to oxidize or not according to the design requirements. The oxidized treatment will give the mesh a black color, which is closer in appearance to the natural environment and more resistant to corrosion.

5. Conclusion

Stainless steel hand woven multiple wire mesh has become an indispensable material in modern design and safety protection due to its unique craftsmanship, excellent performance and wide range of applications. Whether as a highlight of architectural decoration or safety protection, hand-woven wire mesh can meet diversified needs with its flexibility, durability and aesthetics. As technology advances and design concepts are updated, the application areas of stainless steel hand-woven wire mesh will be further expanded, bringing innovative solutions to more industries.